Being in full swing, so-called bio-based plastics seem to be the remedy for the environmental problems that conventional plastics accentuate more. Moreover, they find their place more and more in industrial projects. ِSo what are the encouraging prospects? How can the costs of these plastics be made to be more competitive? How to make their use more practical?

What are bio-based plastics?

Bio-based plastics are composed of polymers and / or fillers of totally or partially renewable origin (starch, sugars, oils, cellulosic materials, etc.). Today they represent the vast majority of bio-plastics produced in the world.

According to the Book "Plants a new oil? By Jean François Morot Gaudry, we can distinguish two types:

polymers with a structure identical to that of their petro-sourced counterparts (example: biobased PE from sugar cane). Having the same properties and same technical performance as the latter, these polymers will therefore require only a minimum investment for their use.

polymers with an innovative structure different from those of existing petrochemical polymers ( example: PLA (polylactic acid) derived from starch). Having specific properties, these polymers make it possible to acquire new functionalities such as that of biodegradability, although these two properties are not linked, that is to say that one can find a biodegradable polymer without being biobased.

What are the advantages and disadvantages of these bio-plastics?

The advantages of bio-based plastics

Bio-based plastics have undeniable advantages:

These bio-plastics which use renewable natural resources give economic opportunities by reducing the recourse to fossil resources and thus the independence in fossil raw materials of the sector [2].

They fight against the increase in greenhouse gases by minimizing the release of carbon dioxide.

They fight against pollut ion. They are either recyclable or compostable.

They help preserve the balance and sustainability of biorefineries (1).

They offer a new outlet for agriculture by stimulating the development of agricultural activities and targeting access to new markets.

They use resources from biomass currently considered as non-recoverable waste (lignin)

The disadvantages of bio-based plastics

In the family of bio-based plastics, there are mainly two drawbacks

The cost: In comparison with conventional plastics, the cost of these plastics is high, which does not encourage consumers to switch to bio-based.

Sorting problems: For example, when collecting biobased plastic waste for composting, for example, there should be no mistake. While it is not really easy to differentiate between these two types of plastics.

In which sectors can bio-based plastics intervene?

The automotive sector

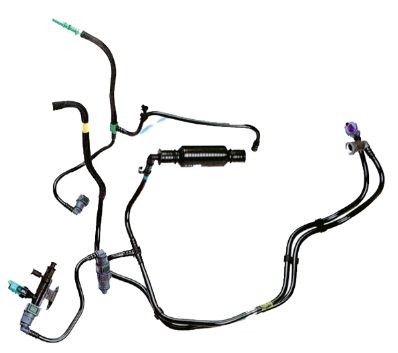

For decades, bio-based polymers have taken place in the automotive sector. Moreover, the polymer PA11 produced from castor oil which is capable of replacing or even surpassing the PA 12 of fo sile origin is used to manufacture, for example, fuel lines used under the hood [3].

ARKEMA Rilsan PA11 Fuel Dispenser

Likewise, in 1930, FORD manufactured automotive interior plastic parts based on soy protein.

Soybean platter

Nowadays, these bio-based plastic materials are used more and more in the automotive sector (dashboards, door trim and certain parts of the passenger compartment), while improving the footprint. carbon of vehicles and by providing increased mechanical strength, weight reduction and absorption properties of acoustics and vibrations [3]

For example, To yota opted for a bio-based alternative for the design of its dashboards and door interior panels by developing a bio-based composite material made of PLA and reinforced with hemp fibers (2) [4].

Hemp plant

The construction sector

Today , thanks to their environmental advantages, the use of bio-based materials appears to be an effective solution to ensure the environmental performance of a building.

And there is already a very wide range of biobased plastics used in the construction sector: insulators based on vegetable fibers, aggregates to reinforce concrete, plastic composites with vegetable fibers… Besides, the biobased materials sector and construction 'has been recognized by the General Commission for Sustainable Development as one of the 18 “green” sectors with strong potential for economic development in the years to come [4].

The packaging sector

The plastic packaging sector is one of the most important outlets for bio-based plastics . Being resistant to grease and constituting a barrier to odors and aromas deemed carcinogenic, bio-based plastics represent the most promising alternative in the field of packaging [4].

We often find po ts of PLA yoghurt, trays for fruits and vegetables made of cellulose or starch.

Bricks and packaging of totally bio-based ice creams

And already for the design of the packaging of its bottles Coca-Cola uses a new bio-based PET based on lignocellulosic raw materials [3]. And even Danone and Nestlé Waters spoke of their combined efforts to launch a 100% biobased PET bottle in 2020 . Again there is a new polymer which should emerge in the market in 2020, the PEF. Being a fully biobased polymer with superior barrier and thermal properties , PEF (polyethylene furanoate) is the ideal candidate for packaging beverages and food or non-food products [5].

The health sector

The honorary president of the association 'plant chemistry' of France 'Christophe Dahlem' affirms that we have managed to find molecules of bio-based origin to replace toxic and carcinogenic substances which can exist in plastics, such as bisphenol A. (a molecule suspected of disturbing organ development and fertility in humans) in polycarbonate and phthalates (Carcinogens) in PVC.

Bisphenol A free baby bottle

What end of life is envisaged for bio-based plastics?

The end of life of bio-based plastics can have two directions: either that they are regenerated and recycled like conventional plastics , or that they will end up being nutritious organic composts.

Recyclable bio-based plastics (reusable)

Biobased polymers having a structure identical to those of petrochemical origin (PE, PET, etc.) have the advantage of being suitable for transformation and granulation using the same recycling channels as these [2].

Compostable bio-based plastics

And as for those with an innovative structure , they are generally compostable. In fact, they have specific properties which make it possible to satisfy new functionalities such as biodegradability. This presents for certain uses, particularly in the agricultural sector, an environmental, technical and economic interest [2]. Let us cite as an example mulching films, because once this film is used, its fragments will end up biodegrading while enriching the soil with organic matter and nutrients [6].

Conclusion

The ubiquity of plastics (petro-chemicals) which take several years or even decades to degrade generates environmental disasters, such as the exhaustion of petroleum resources (non-renewable), global warming induced by the increase in greenhouse gases greenhouse and pollution. Hence the urgency to switch to bio-based plastics. The latter seem to be the most miracle solution.

Automatic translation