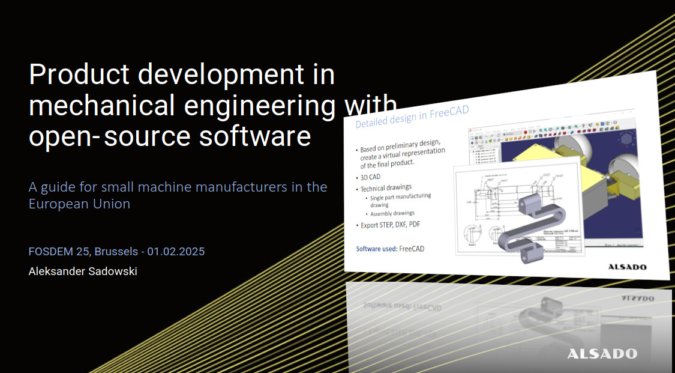

A Blueprint for Open-Source Product Development

Aleks’s methodology demonstrates how lightweight tools can replace proprietary suites without sacrificing functionality. His workflow begins with requirements management and patent research in LibreOffice Calc, progresses through conceptual design in spreadsheets, and transitions to 3D modeling in FreeCAD and simulation in PrepOMax. Notably, the approach integrates product safety (CE marking) early in the process using the same open-source tools. The final stages highlight two PLM options: a self-hosted system for data control or Google Drive for accessibility. This end-to-end process, documented in his FOSDEM talk, proves particularly valuable for resource-constrained teams.

The PDM Paradox in FreeCAD’s Ecosystem

A central tension emerges around Product Data Management (PDM). While commercial CAD packages like SolidWorks enforce single-part-per-file structures that align neatly with PDM systems, FreeCAD’s flexible document model—where multiple parts, assemblies, and drawings coexist in one file—breaks traditional PDM assumptions. Forum participants like Serchu observe that existing open-source PDM solutions (FreePDM, Taack PLM) only track whole files, creating management gaps. Historical precedents like I-DEAS (which managed internal objects) are cited as potential models, suggesting FreeCAD-compatible PDM must operate at the object level rather than the file level.

Emerging Solutions: From Databases to Decentralization

Practical solutions discussed fall into three categories: First, database-centric approaches pairing PostgreSQL with NextCloud for metadata and file storage, creating a searchable engineering vault. Second, a Python-based decentralized PDM prototype (shared via forum attachments) where each user maintains local control with synchronization capabilities—an architecture mirroring Git’s philosophy but tailored for CAD data. Third, workflow conventions like enforcing one-part-per-file rules, though this sacrifices FreeCAD’s flexibility. Crucially, participants emphasize that any system must handle version conflicts and partial updates when components are modified independently.

Adoption Challenges and Community Dynamics

The discussion reveals a paradox: While robust PDM/PLM could make FreeCAD viable for businesses, most current users (hobbyists, freelancers) lack incentive to adopt such systems. As user grd notes, "The hassle [of PDM] can be too much" without team collaboration needs. Corporate adoption remains limited by FreeCAD’s evolving feature set, creating a chicken-and-egg problem for PDM development. However, tools like Recoll for document search and nanoPLM (Aleks’s proposed solution) show how incremental improvements can bridge this gap. The thread ultimately reflects open-source’s core strength—collaborative problem-solving—with engineers, developers, and tinkerers collectively iterating toward professional-grade solutions.

Conclusion: Pathways to Professionalization

This forum thread maps both the maturity and frontiers of open-source mechanical engineering tools. Aleks’s workflow proves that core product development tasks can already be accomplished without proprietary software, while the PDM debate highlights where innovation is still needed. The most promising developments combine technical solutions (like object-level version control) with social ones (community standards for file organization). For open-source CAD to cross into mainstream professional use, these discussions suggest that PLM/PDM development must parallel improvements in modeling and simulation capabilities—a challenge the community appears ready to tackle.