In this article, we use the "Smart Little People" technique and we compare CAD features to employees and a 3D part to a company.

“Smart Little People are imaginary tiny beings who represent the different elements of the problem we are trying to understand and solve” Karen Gadd (Book: TRIZ for Engineers)

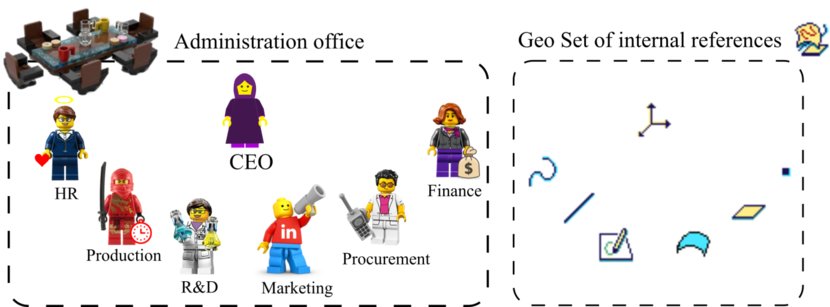

CEO / Absolute axis system

Every part should have an absolute axis system that controls its position and orientation. It’s generally the origin of all other features.

Every company should have a CEO that orients its activity.

Advice 1: Use one reference instead of seven

One axis system can replace seven references (1 origin + 3 directions + 3 planes). It’s like a competent CEO that does the job of seven managers.

Managers / Internal References

For a small startup the CEO, by himself, can manage a group of engineers and technicians. As the activity rises he needs managers for support.

The same situation applies to the 3D part. As the design gets complicated, internal references (points, lines, planes…) are created to transmit information from the axis system to sketches and solid features.

Advice 2: Managers should work in a separate office

Internal References should be grouped in a separate Geometrical Set similarly to the administration office for managers.

The designer may create multiple sub geometrical sets for a better organization. It’s like having multiple offices in the administration department.

Advice 3: Organize internal references by type or by function

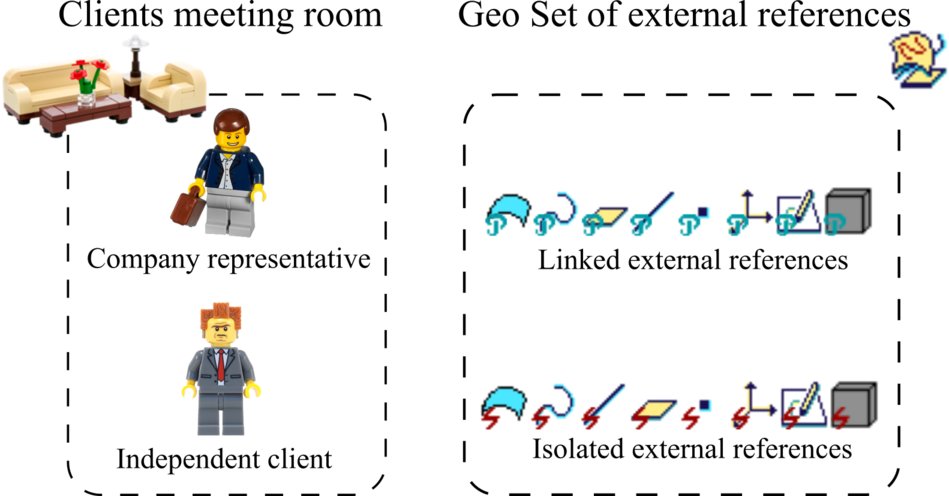

Clients / External References

Besides the CEO, managers take instructions from clients. External References function as input information for internal references and other features.

Linked external references are like representatives of another company. They depend on their superiors in the original company.

Isolated external references are like independent clients. They have no superiors. They can change decisions independently inside the hosting company. Isolated references too can change their position and orientation independently inside the part.

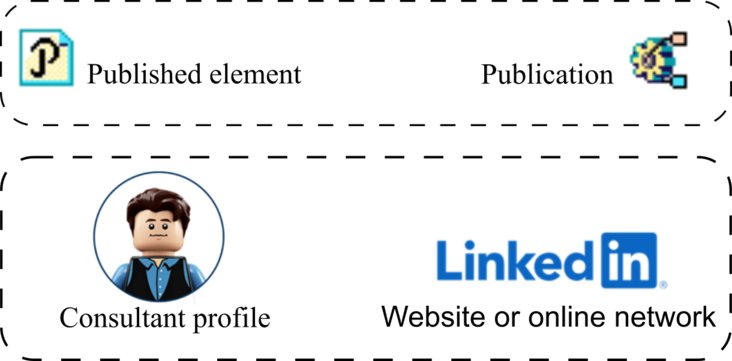

Advice 4: Use publication

As an entrepreneur, you want to dispatch some employees to other companies for consultancy. You publish their profiles on the internet, informing the public that these experts are available. Like clients, they provide instructions to employees in the hosting company.

As a designer, you should publish features which you intend to transfer to another 3D part.

Advice 5: Hire independent auditors

Some companies hire auditors to inspect and improve the process or the product before manufacturing and delivery.

Some designers create isolated references in the part for the same reasons. They are useful to test and validate the 3D design before delivery. Then they may be replaced by linked external references or converted to parametered internal references.

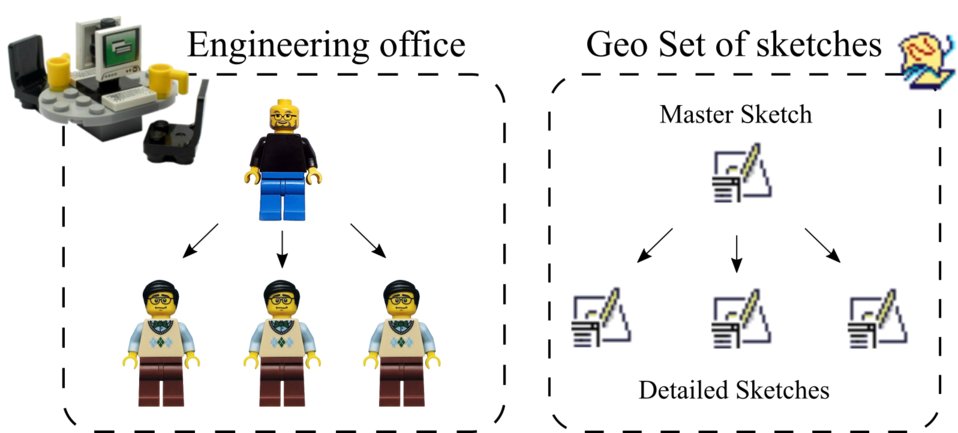

Engineers / Sketches

Engineers transform the client’s specification into technical solution while respecting the company’s objectives and constraints. They get all needed instructions from clients, managers and maybe other engineers.

In 3D, sketches are like engineers. they contain the technical solutions. External or internal references or other sketches may serve as inputs.

Advice 6: The importance of a team leader

Let’s suppose you have three sketches. One depends on another. It is better to create a new one that contains only functional curves (concept curves). This sketch serves as a reference for the three other ones.

It’s like recruiting a team leader for a group of engineers.

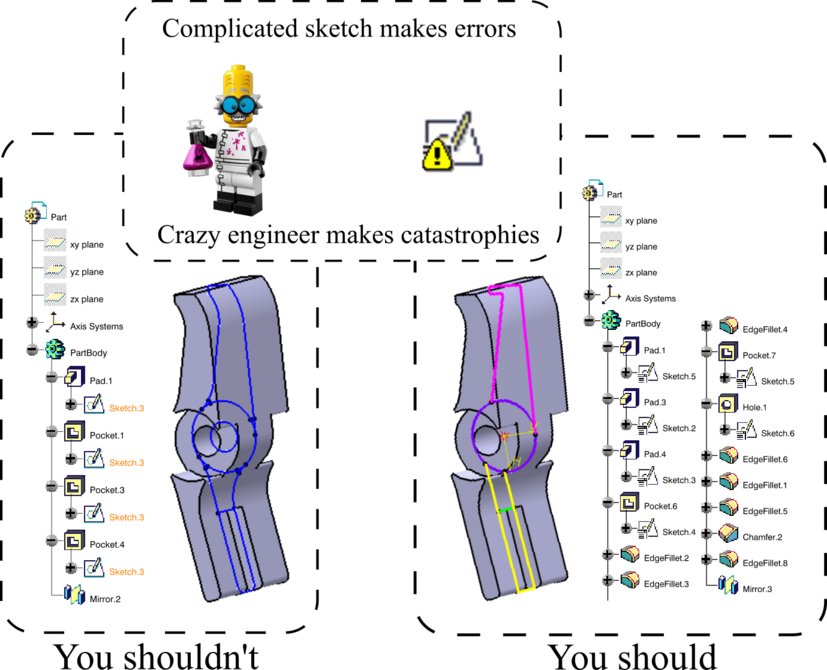

Advice 7: Go easy on your engineer

Simplify your sketches. Don’t create forms that can be made by geometrical references or solid features. Don’t give your engineers tasks that can be made by managers or technicians.

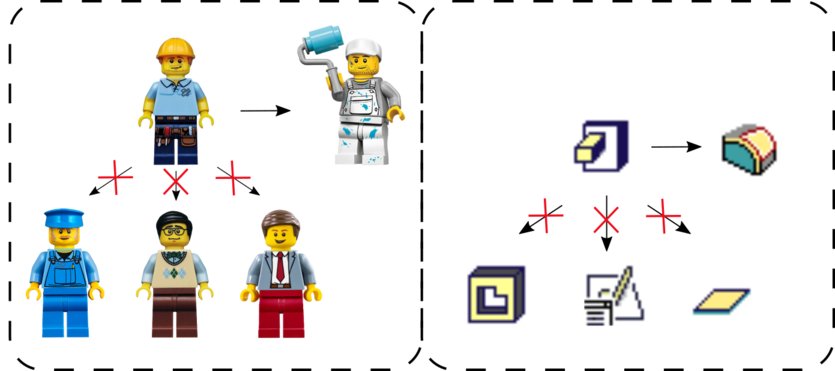

Technicians / Solid features

Technicians are like solid features (extrusion, hole…). They produce the final result. They transform the detailed instructions prepared by engineers into a tangible product.

Solid features transform the detailed sketches (or developed surfaces) into a 3D solid geometry.

Advice 8: Technicians should not give orders

Generally, a technician does not give instructions, either to a manager, an engineer or another technician.

Avoid the use of topological elements (vertex, edge, face) of solid features as references unless for dress-up features. For example, avoid using a planar face as sketch support.

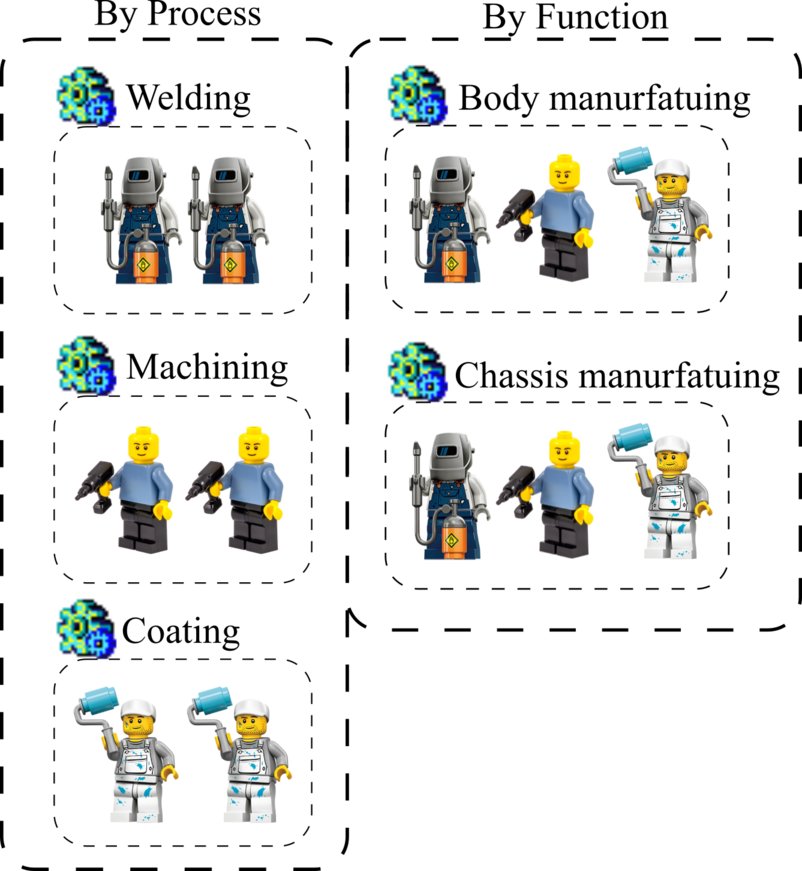

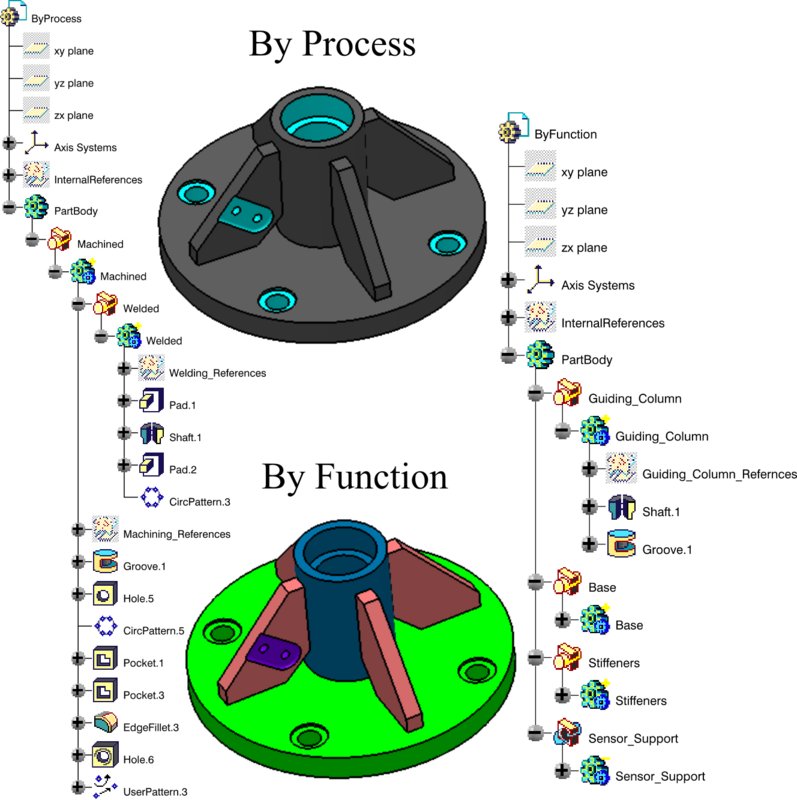

Advice 9: Work with modular units

Solid features should be separated in modular independent bodies based on function or process. These bodies should contain their internal references. They can be developed independently or exchanged separately with teammates, providers or clients.

It’s like dissociating the manufacturing of the chassis from the body in two distinct plants.

Advice 10: Name your Features

"Employee.10" should not be a name for your employees nor your CAD features. Giving meaningful names helps a lot to modify the design of others or even yours after a while.

It's your turn!

The analogy looks relevant. It encourages critical and creative thinking.

Would you share with us some pieces of advice to improve the management of CAD features?