Machine/installations design is not guided by any rigid rules; however design is not a random procedure either. There are a number of factors that can aid a machine design process. It is very important to understand the process of mechanical machine design and follow this process to develop machine/heavy equipment designs that deliver the best performance. Let us have a look at the general procedure for machine design that helps an engineer tailor dedicated mechanical equipment designs that perform better, are durable and are easy to manufacture.

Understand the Requirements:

The first step of engineering a high performance machine is recognizing the need i.e. understanding the purpose of design. Preparing a complete statement of the problem that includes details about the aim or purpose for which the mechanical design project is proposed.

Making the written statement:

Make the written statement of what exactly is the problem for which the machine design has to be done. This statement should be very clear and as detailed as possible. If you want to develop the new produce write down the details about the project. This statement is sort of the list of the aims that are to be achieved from machine design.

Consider the past experience:

If you have the past experience of designing the machine element or the previous records of the company, consider them and make the necessary changes in the design. Further, designer can also consider the personal judgment so as to facilitate the production of the machine and machine elements.

Analyze and Evaluate the Design Mechanism:

Shortlist and analyze various possible mechanisms for the machine. Consider the possible mechanisms, so when you designing the machine consider all the possible mechanisms and solutions which help desired motion/function or the group of motions/functions in your proposed machine. From the various options the best can be selected whenever required.

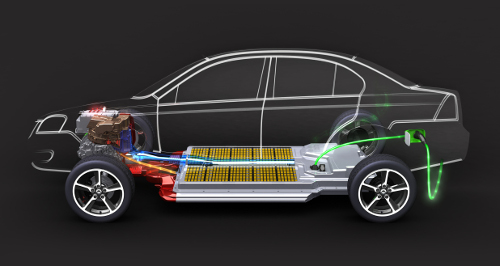

Analysis of Forces / constraints /conditions:

Analyze how every component of a machine with fit in and interact with each other (forces, heat, chemicals, electromagnetic, electrostatic, radiations ...) , also analyze what forces and constraints or conditions act on each and every component of the mechanical equipment and the energy transmitted by each component. The result of analyses must, in most cases, return numerical values and/or clear characteristics that can be used as parameters to design ans choose machine/installation elements. It is also important to define Find allowable/limits of use and : All the machine elements are subjected to stress/constraints whether small or large. Considering the various forces/charges/use conditions, acting on the machine elements, their material and other factors that affect the strength/resistance/life of the machine/product/part calculate the allowable or design stress for the machine elements.

Design / parametrization of Elements:

All the components of equipment are subject to stress and other forces/conditions during operation. These stresses affect the strength of the machine. Hence analyzing these working conditions is important to design mechanical/machine equipment that is durable and can endure the stresses of real world working conditions.

Dimensions/Properties of the machine elements: Find out the appropriate dimensions/materials for the machine elements considering the forces/constraints acting on it, its material, and limits of use (design stress for example). The size of the machine elements should be such that they should not distort or break when loads are applied / in working conditions.

Selection of the standards parts / components :

When the list of components is defined and the characteristic of each part is known, consider the choice of what parts can be selected from constructor catalogs that are ready-to-use. This is strongly recommended in order to save time and money.

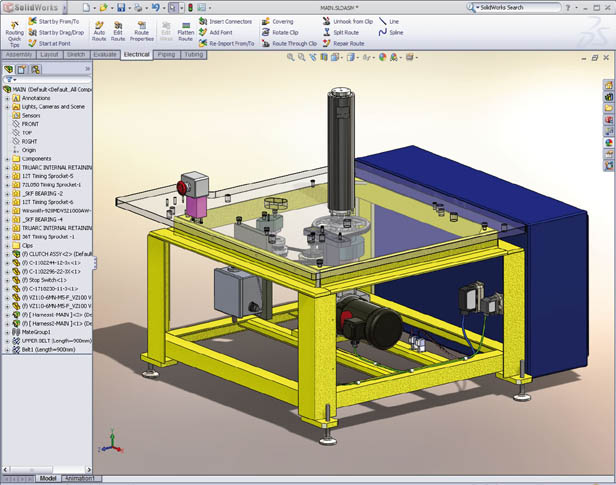

Make drawings / documentation

After designing the machine and machine elements make the assembly drawings of the whole machines and detailed drawings of all the elements of the machine. In the drawings clearly specify the dimensions of the assembly and the machine elements, their total number required, their material and method of their production. The designer should also specify the accuracy, surface finish and other related parameters for the machine elements. It is important also to create a detailed Mechanical Drawings of each component lonely and the total assembly of the machine/installation. Complete specification using CAD software can be of great assistance for manufacturing process/repairing and recycling.

Design Iteration for Manufacturing:

Design changes, that facilitates easy manufacturing the machine and its components is advisable in condition not to affect the performance of the product/machine/parts.